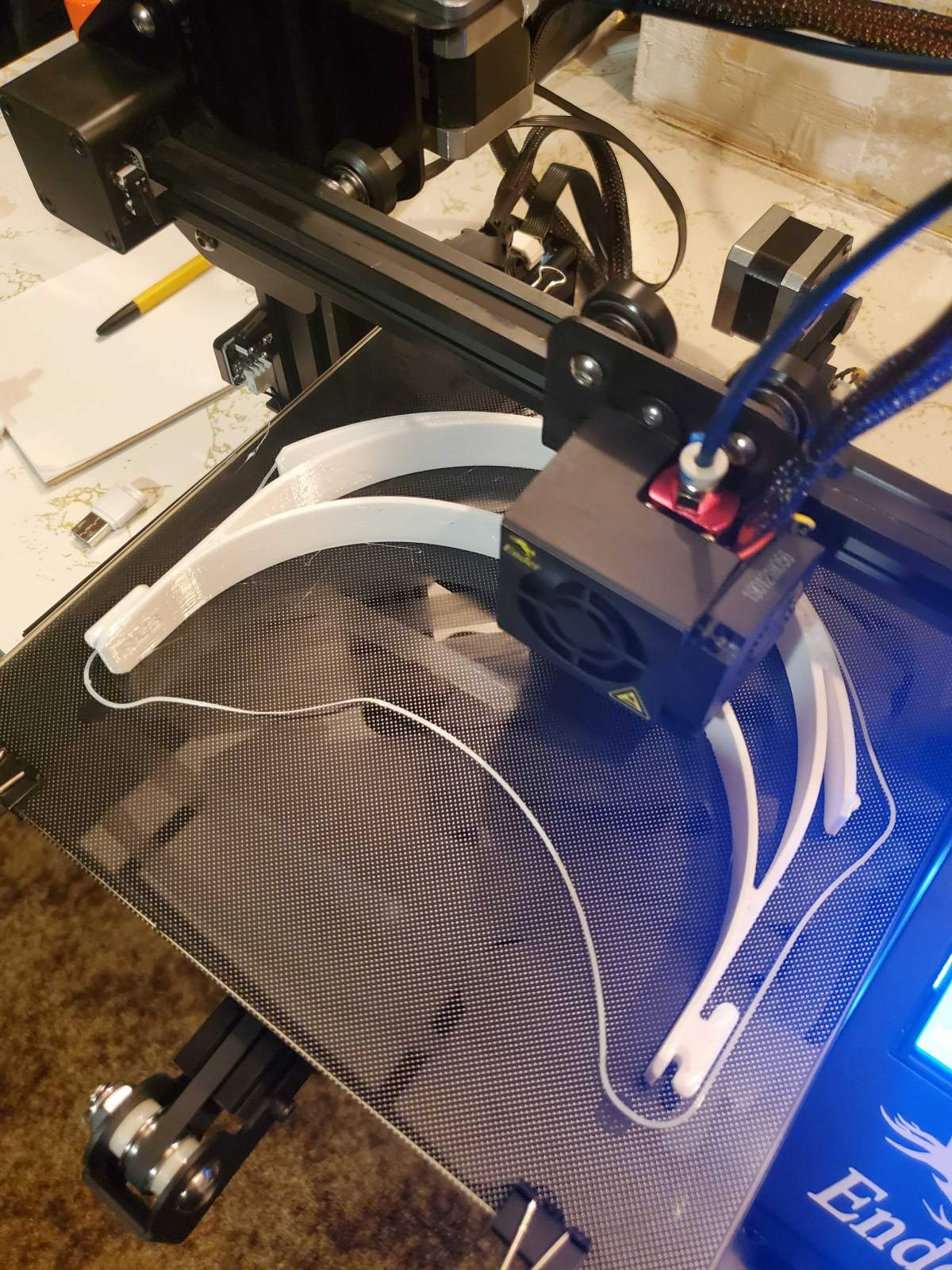

Faculty and staff at the University of Alberta have started making 3D-printed face shields in hopes of helping facilities keep up stocks of personal protective equipment (PPE) through the COVID-19 pandemic.

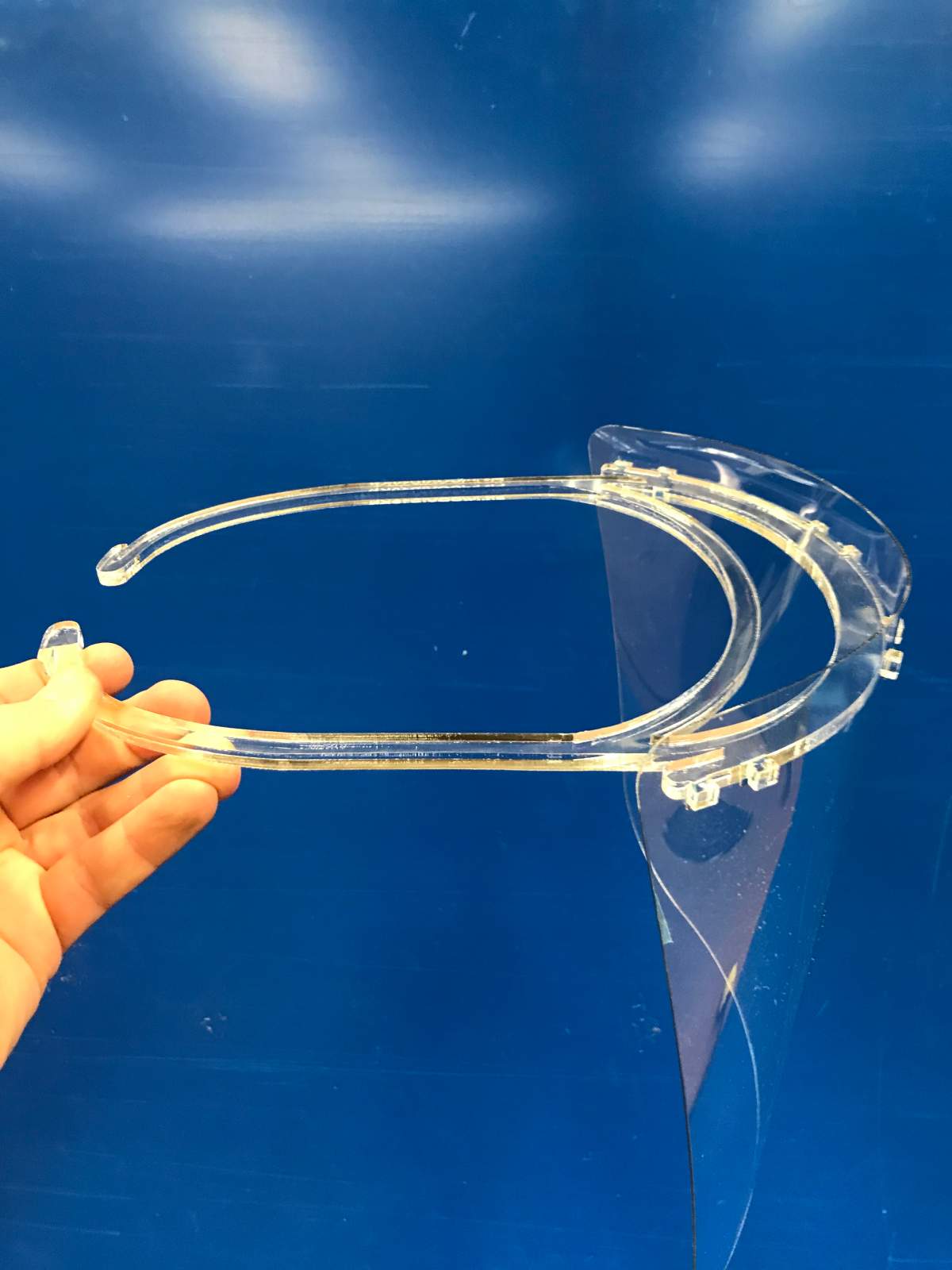

The group behind the project is made up of clinicians, engineers and designers working alongside Alberta Health Services to make 2,000 face shields that are reusable and safe. The U of A said they have received Health Canada’s approval to manufacture the shields.

Alberta Health officials expect the number of COVID-19 cases to peak in mid-May. The team at the U of A said it is racing to create the PPE to give to health-care workers.

The group said an initial batch has already been piloted at the University of Alberta Hospital for feedback from health-care workers.

“We’re not trying to replace what we have and what is proven,” said Charles Larson, a U of A clinical assistant professor in pediatrics and pediatric cardiac intensivist at the Stollery Children’s Hospital.

“What we’re trying to do is create a product that we could use if we run out of PPE and we start seeing shortages the same way that other jurisdictions have… We can’t afford to get health-care workers sick.”

If AHS doesn’t end up needing the face shields right away, Larson said the PPE will be rerouted to Alberta nursing homes.

The team will work with AHS to develop a protocol to safely use and clean the reusable face shields.

Several other partners are involved in the project, including the Elko Engineering Garage, an Engineering at Alberta maker space, Karma Machining & Manufacturing, as well as a number of charitable groups.

Get weekly health news

“It’s incredible and so very generous of them,” Larson said. “There are people all over Edmonton who are keen to do this work.

“According to Health Canada, as long as there’s a centralized area to do quality control and to take a look at these products, anyone can print medical devices and send them in. So this is completely legitimate and makes a lot of sense in a crisis situation.”

The material cost to produce one face shield is about $12, according to the university. Early prototypes were funded out of pocket by the team. Now, a GoFundMe page has been set up to help cover the production costs. The U of A said the money raised will be administered by the University Hospital Foundation.

Production on the 3D-printed shields begins this week.

The group is also working to build other devices to help during the health crisis, including clear acrylic boxes that can be put over patients when their breathing tubes are removed, to minimize aerosol exposure.

Comments