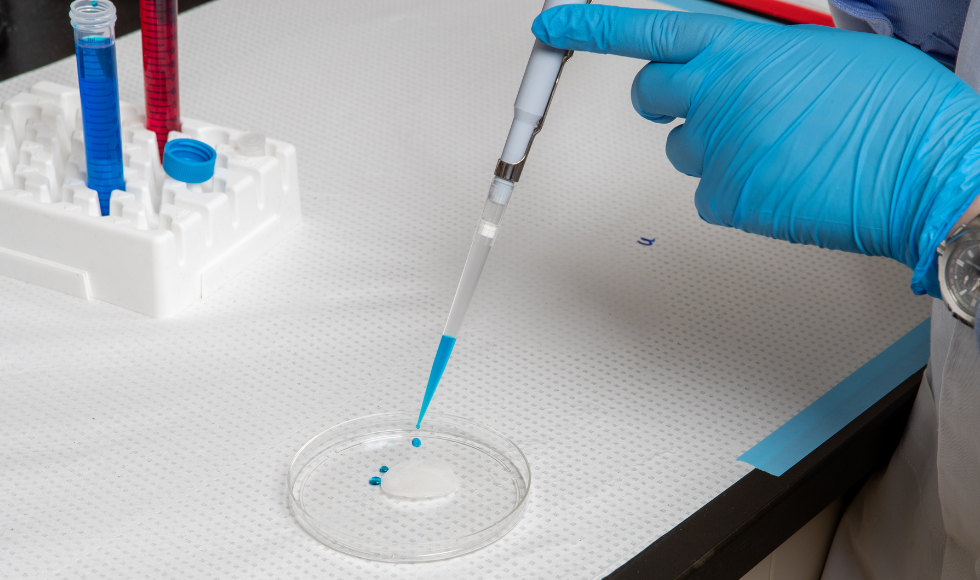

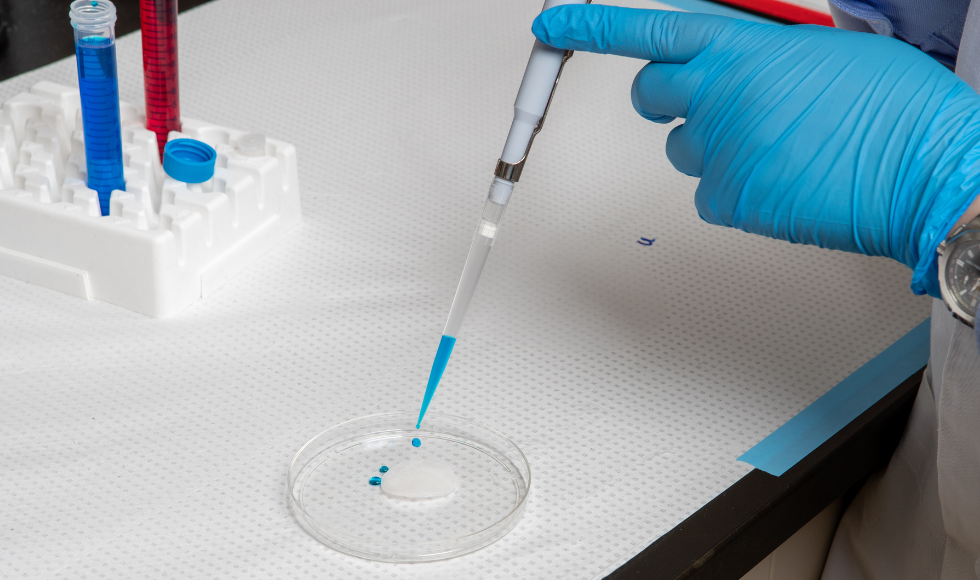

McMaster University researchers in Hamilton say a promising pathogen-repellent wrap they’ve created could protect against contamination on high-touch surfaces such as door handles and railings.

The so-called ‘RepelWrap’ is a simple plastic wrap with a built-in microscopic structure that helps to repel things like bacteria and viruses.

Dr. Leyla Soleymani, associate professor Tohid Didar and others with the McMaster School of Biomedical Engineering published their first proof-of-concept research in December 2019, on the eve of the COVID-19 pandemic.

The inventors believe their licensed technology has huge potential amid a worldwide viral crisis that led to more than 450 million COVID-19 cases between 2020 and 2022.

Get weekly health news

“So … if you touch with a contaminated hand a regular surface, contamination will get transferred to it,” Soleymani told 900 CHML’s Good Morning Hamilton.

“But if you touch the repel wrap, it doesn’t get contaminated. The contamination stays on your hand.”

Two more papers were published in late February with one revealing a method that transforms the wrap into highly flexible films that repel pathogens and prevents blood clots which could service medical equipment – like catheters and tubing.

The other study showcased the effectiveness of the wrap at repelling both bacteria and viruses.

Soleymani characterizes the wrap as like “Teflon in plastic” which is extremely non-sticky because of its structure, both physical and chemical.

She says the team came across the potential product “somewhat accidentally” through five to six years of study in developing a structure for another application.

“We realized nothing sticks to this when when we were running experiments with blood and other physiological samples,” said Soleymani. “Things we’re not getting absorbed to it, and we thought, ‘OK, how about we explore a new application.'”

Researchers suspect the wrap could potentially be utilized on things like elevator buttons, door handles, food packaging or medical devices that get inserted into the body.

While the wrap is still in it’s prototype stage, the final product would be in “big rolls” sent to customers who could cut the material into smaller sheets.

Soleymani suspects the timeline for hitting the marketplace is maybe one to two years.

Comments

Want to discuss? Please read our Commenting Policy first.