It’s an unpleasant sound that usually comes with an unwelcome financial hit: squealing brakes.

Yet, as every motorist knows, having bad brakes can lead to a very bad day.

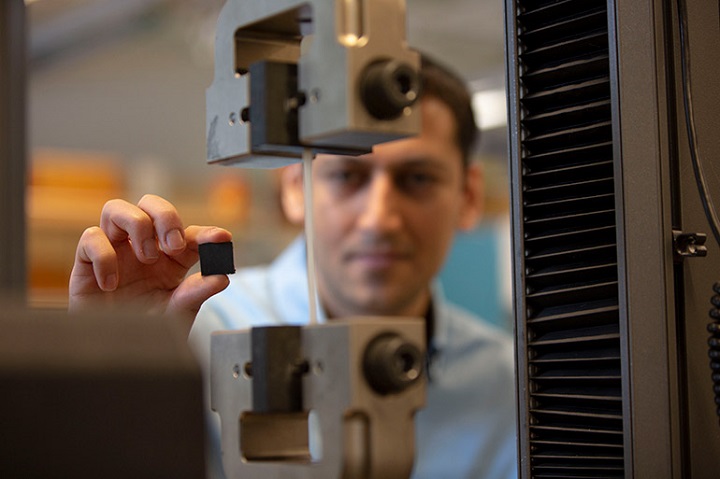

Enter University of British Columbia Okanagan engineering researcher Mohammad Arjmand, who is helping to develop a new brake pad that could improve braking systems in vehicles and trains.

Working on the project are researchers at UBC Okanagan, the University of Toronto and Sharif University of Technology in Iran. Apparently, the key is mixing carbon fibres into the polymer-based pads.

Arjmand, an assistant professor, says the new and improved brakes can prevent wear and tear and have better frictional properties than brakes currently on the market.

“No researcher in Canada is currently working in this area, and the work is very important for the automotive and railroad industries,” said Arjmand, one of the lead researchers on the project.

Get daily National news

WATCH (Feb. 15, 2018): Failure to brake on time could cost a life — Winnipeg driving experts

Brake pad materials are typically available in three categories: metallic, ceramic and organic. All have benefits and weaknesses inherent to their design, such as cost, durability, noise, slow response time or increased temperature during usage, he adds.

UBC Okanagan cited statistics from the U.S. National Highway Traffic Safety Administration, which said vehicle-component failure accounts for nearly two per cent of crashes, and about 22 per cent of vehicle-component faults are caused by brake-related problems.

“This new research looks at things like composite breakdown during high temperatures, durability, friction and wear testing,” said Arjmand.

“Our findings show that the newly designed carbon-fibre-polymer brakes represent an acceleration in the science of deceleration and could be a real boon for the industry and consumers alike.”

He added this could lead to smaller brake pads that are more efficient and cost-effective since the small pads can withstand greater friction and temperatures.

“As we continue to develop nanomaterials and mix them with polymers to develop multifunctional composite cocktails that can address issues such as friction, wear and heat distribution at the molecular level, we will continue to help the industry evolve,” Arjmand said.

Comments

Want to discuss? Please read our Commenting Policy first.