A company in Halifax is getting international recognition and praise for developing a green technology that aides in reducing greenhouse gas emissions during the concrete manufacturing phase, the most common construction material in the world.

With five per cent of all CO2 emissions coming from cement production, CarbonCure Technologies in Burnside is looking to reduce that number by retrofitting concrete plants all over the world with their technology.

The Technology

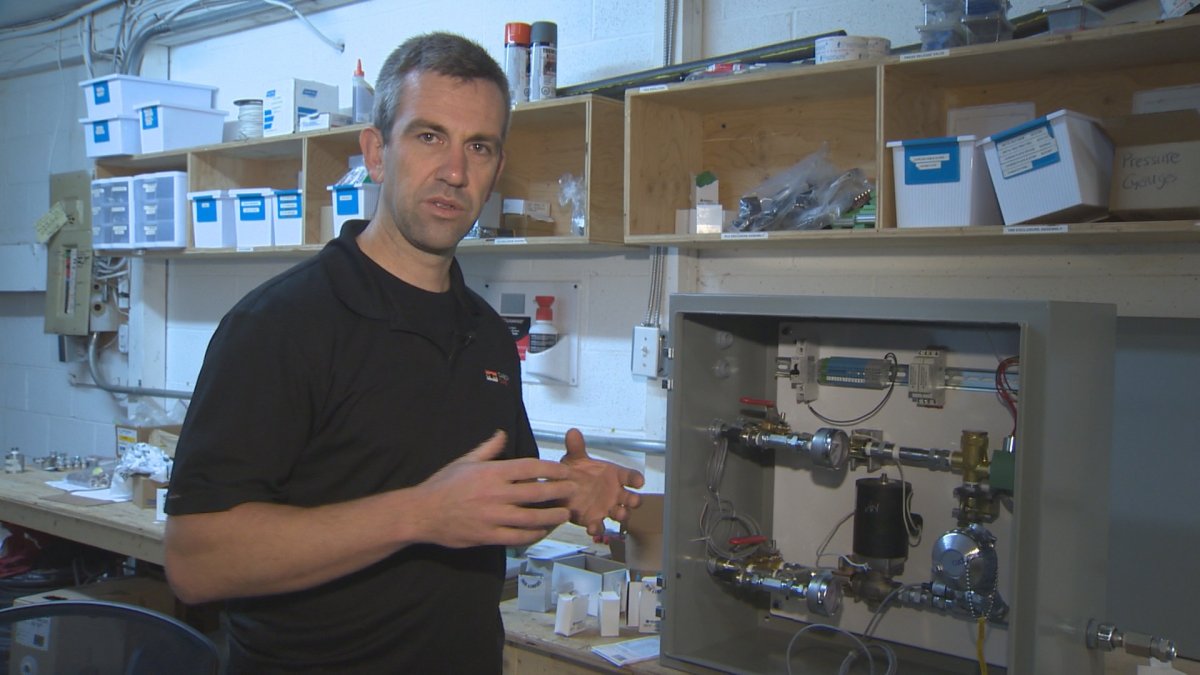

CarbonCure retrofits existing concrete plants with their equipment to recycle waste carbon dioxide or C02 emissions from big emitters such as refineries. That C02 is then mixed with cement to produce a stronger, faster setting concrete that has a 10 to 15 per cent lower carbon footprint.

“The C02 is a gas and that reacts to the chemistry of the cement within concrete and it actually turns that C02 into a nano material. So we are making a a very fine nano material within the concrete. Which gives concrete this higher strength performance. It’s good for business and for the environment which is a very unusual formula,” said Rob Niven, the CEO of CarbonCure.

The company has seen huge growth in the last six months, expanding to over forty concrete producers across North America.

“It’s gone from this idea into now technology that’s out in to world being produced and supplying hundreds of projects all around North America,” said Niven.

According to the company, if CarbonCure was adopted by all concrete producers it would eliminate one megaton a year of C02 production and provide 400 million in cost savings.

Acclaim

For their efforts, CarbonCure has been selected as a semi-finalist for the Carbon XPRIZE, an international competition that challenges teams to develop breakthrough technologies that convert the most CO2 into one or more products with the highest net value.

The prize is $20 million. Niven’s calls the recognition humbling.

“But I can tell you the recognition of being an XPRIZE winner is probably worth ten times that. Being able to operate at that platform or that stage where everyone in the world is going to know about CarbonCure is very exiting,” he said.

CarbonCure technologies was also recently awarded with the 2016 Ernest C. Manning Innovation Award. The Manning Awards annually recognises Canadian innovation across multiple disciplines.

Carbon Tax

While the Nova Scotian government has dismissed a provincial carbon tax which has been pushed by the federal government, Niven says it would be good for his business and other green technology businesses.

“A carbon tax would spur a lot of innovation and help building companies like CarbonCure as the demand increases. If a carbon tax is imposed here in Nova Scotia, it would be very good for business.”

The Future of CarbonCure

Where does Niven see CarbonCure in the future? Niven says he hopes the recent national and international acclaim will lead to more concrete producers adopting the technology.

The company has grown to over 20 employees at their Halifax firm and they employ dozens of researchers across Canada.

Niven says no matter the direction the company grows, he is proud of the team’s work and that the work was done in Nova Scotia.

“The fact that it’s done here in Nova Scotia is incredible to be part of. To have this innovation right here and also to be working in clean technology has helped our staff and me get motivated,” said Niven.

- Invasive strep: ‘Don’t wait’ to seek care, N.S. woman warns on long road to recovery

- Ontario First Nation declares state of emergency amid skyrocketing benzene levels

- Do Canadians have an appetite for electric vehicles? Experts are divided

- Nearly 200 fossil fuel, chemical lobbyists to join plastic treaty talks in Ottawa

Comments