TORONTO – From incredible stories of successful body-part transplants, to controversy surrounding easy access to weapons online, 3D printing is the latest technology craze.

In the medical community, a 3D laser printer and plastic particles were used to create an airway splint to save the life of a baby boy suffering from a birth defect that caused him to stop breathing almost daily.

The successful transplant was described as a “medical first.”

3D printing has also helped to create a bionic ear, which researchers say can hear radio frequencies a million times high than a human ear.

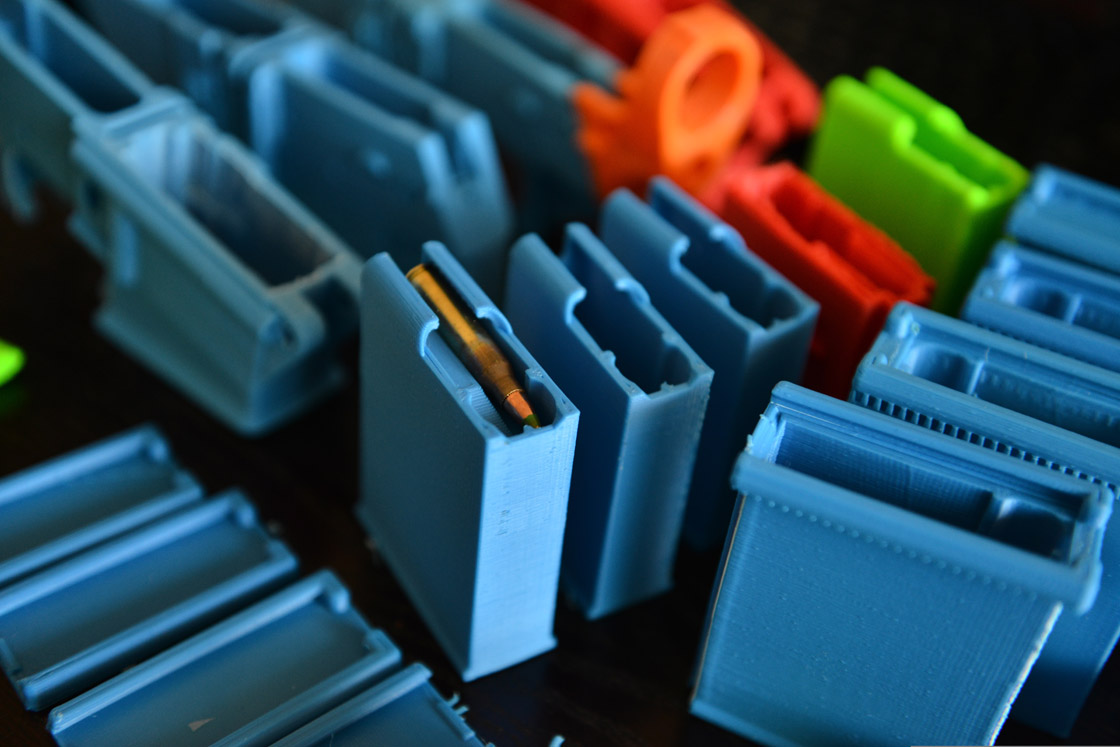

Earlier this month the technology sparked controversy after blueprints for a 3D printed gun called the ‘Liberator’ surfaced online. With access to a 3D printer, anyone would have been able to download the blueprints and print out a gun capable of firing eight or nine rounds for about $60.

The gun’s blueprints have since been removed from the website Defcad.org at the request of the U.S. Department of Defense Trade Controls.

Just last week, a video was uploaded to YouTube showing test-firing of 3D printed bullets.

The technology has also raised concerns surrounding copyright and patent laws.

Companies can trademark 3D objects that are imperative to the brand’s appearance – for example, Coca Cola holds the trademark for the Coke bottle – the shape and appearance of which is iconic to the Coke brand.

So if someone were to use a 3D printer to replicate that bottle they would technically be breaking copyright law.

Experts have cautioned that copyright laws won’t be able to keep up as 3D printers become more affordable to average consumers.

How exactly do 3D printers work?

Design

In order to create a 3D-printed object, a user must first design a blueprint for the object by using computer aided design (CAD) or animation modelling software.

- Enter at your own risk: New home security camera aims paintballs at intruders

- Boston Dynamics unveils ‘creepy’ new fully electric humanoid robot

- Ontario First Nation calls for chemical plant to be shut down amid ‘dangerously high’ benzene levels

- Nova Scotia scraps spring bear hunt idea, public ‘very divided’ on issue

If you aren’t design-oriented, there are multiple design sites that house hundreds of blueprints for 3D objects, including Thingiverse, Shapeways and Sculpteo. Users can download anything from iPhone case designs, to jewelry and even intricate sculpture designs.

Printing

3D printers use melted plastic materials poured in layers – some as thin as one-tenth of a millimetre – to recreate the image shown on the blueprint. Just like a traditional ink-and-paper printer, the nozzle moves back and forth over the print surface, layering the material to create the 3D object.

The printers can use a variety of materials to create objects with. The PandaBot, made by Toronto-based startup Panda Robotics, uses a material called acrylonitrile butadiene styrene (ABS) – the same material used to make Lego bricks and some small kitchen appliances.

More advanced uses include “bio-printing,” which is used in the medical field to create tissue samples by using “bio ink” – a mixture of biodegradable gel and real human cells. These printers can scan real body parts and recreate them using bio ink – an ear for example, takes four to six hours to make.

Comments