WASHINGTON – In a striking example of how 3-D printers could customize medical care, doctors turned powdered plastic into tiny devices that saved the lives of three baby boys by holding open defective airways so they could breathe — and the implants even expanded as the tots grew.

These experimental airway splints actually change shape over time, adding what researchers call a fourth dimension that is key for growing children as the implants first expand and later, when no longer needed, harmlessly dissolve.

“We are using laser light to transform dust into medical devices that change how the body develops,” said lead researcher Dr. Glenn Green, a pediatric ear, nose and throat specialist at the University of Michigan. “It is a concept that would have been inconceivable” not too many years ago.

Green’s team made headlines in 2013 with initial success in treating the first baby, Kaiba Gionfriddo.

READ MORE: 3D printing tech provides cheap, lightweight ‘robohand’ to 7-year-old US girl

On Wednesday, the researchers published promising results with two other youngsters, plus long-term tests showing that Kaiba, now a thriving 3-year-old, seems cured as the splint that once helped him breathe is dissolving right on time.

Next the team is working with the Food and Drug Administration to begin a clinical trial testing the 3-D printed devices in 30 children with a similar problem.

Independent experts called the work exciting.

- Bird flu risk to humans an ‘enormous concern,’ WHO says. Here’s what to know

- ‘She gets to be 10’: Ontario child’s heart donated to girl the same age

- Shoppers faces proposed class action over claims company is ‘abusive’ to pharmacists

- Most Canadian youth visit dentists, but lack of insurance a barrier

“Fascinating,” said Duke University’s Dr. Piers Barker, who leads research in 3-D printing for pediatric cardiology.

“The promise of 3-D printing is you can really begin to personalize potentially almost every medical intervention,” Barker said. But “this approach to a structure that permits growth — this is the first time I’ve seen anything like this.”

Beyond all the consumer gadgets from the 3-D printing revolution, doctors increasingly are turning to the technology.

READ MORE: Father uses 3D printer to make prosthetic hand for daughter

They already have tried printing custom-sized artificial bones, replacement ears and models of deformed hearts so that surgeons can practice a fix before cutting someone open. Some scientists even are attempting to print organs, pumping out a mixture of biodegradable scaffolding and human cells instead of ink. Such work will take many more years of research.

The airway splints mark a different approach, not replacing a body part but helping it grow with a made-to-order therapy.

About 1 in 2,000 babies is born with weakened airways, called bronchi, that can suddenly collapse and block breathing. Most outgrow the condition by age 3, because airways get stronger as they get larger. But severe cases can be life-threatening.

All three boys in the Michigan study had undergone tracheostomies, to attach them to ventilators, and yet repeatedly had to be resuscitated.

“He was basically suffocating,” Meghan Orbich said of her son Ian.

At just 5 months old, Ian had spent weeks in intensive care, his breathing repeatedly stopping. Frustrated specialists in his hometown of Pittsburgh didn’t know what else to try. Orbich saw a news article about the Michigan research and tracked down Green.

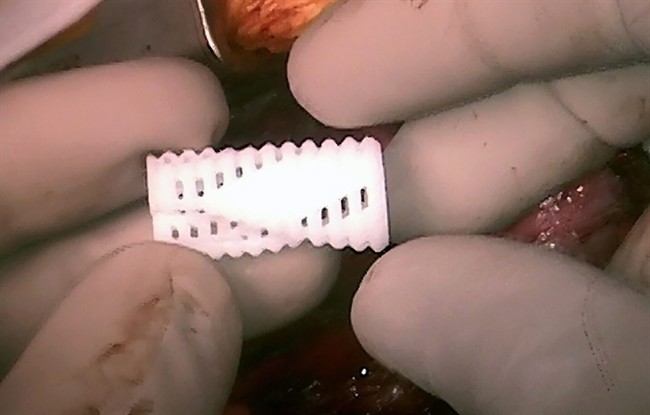

Previous attempts at propping open airways from the inside hadn’t worked very well. So Green and biomedical engineer Scott Hollister designed a splint to be stitched to the outside, holding open the airway much like a pole holds up a tent.

Using measurements from each patient’s CT scans, in a single day the laser printers churned out tubes the right shape and size for each child, with an opening down one side. The splints are made of thin layers of plastic known to start degrading in about three years, just the right time.

Surgeons sterilized the splint and placed it over each patient’s weakened airway. As that airway eventually doubled in size, it pressed on the splint and widened the opening, Hollister explained.

The surgeries required emergency permission from the FDA, which says new 3-D implants must meet required performance standards just like traditionally manufactured medical devices. Green said the materials for a splint cost about $10, and despite surgery fees the approach promises to save money by getting kids out of the hospital sooner. He and Hollister have filed a patent application for the device.

On Wednesday, the researchers reported that all three boys are improving dramatically, living normally at home. Ian is the last remaining on a ventilator because of additional problems.

But a year after the implant, “he is doing amazing,” his mother said. “It was a blessing.”

Comments