Since the start of the COVID-19 pandemic, thousands of Canadian companies have answered the federal government’s call to abandon business as usual and start making face masks, ventilators and gloves.

A handful of those companies are in the Maritimes, but according to Nova Scotia’s life and health sciences industry group, BioNova, some of them were not prepared for the strict federal guidelines that come into play when making medical gear.

Anyone who wants to sell or provide PPE to a medical facility must be authorized by Health Canada, which also lays out the materials, testing, and production requirements for each item.

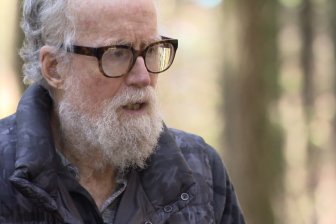

“It’s great that these companies are stepping forward, but there are a lot of regulatory hurdles that need to be overcome,” explained BioNova CEO executive director Scott Moffitt.

“The Health Canada regime is pretty much an unknown entity unless you’re a medical technology company.”

READ MORE: Nova Scotia sees record spike in cases, all identified in central zone

Health Canada’s website lays out the specifications for producing COVID-19 equipment. They include everything from the required filtration efficiency for submicron particulates in disposable face masks to the level of pressure a glove must withstand before it pierces.

Steen Gunderson, president and CEO of Bouctouche Bay Industries (BBI) Group in Saint-Édouard-de-Kent, N.B., said making PPE has been a “steep learning curve and possibly a learning cliff.” The company normally produces aquaculture and agriculture equipment, and is now making two face shields every 35 seconds, thanks to injection molding.

“We had designed something we thought looked great, but we needed to add a little bit of technical information in there, and the just operational procedures,” he told Global News.

“So as we’re manufacturing, making sure we’ve got full traceability on our materials… so if we have a box or a batch that there are any questions on, we know exactly when it was made and by who it was made, and what it was made with.”

READ MORE: Nova Scotia taps private sector for pandemic supplies and services

BBI Group is one of a handful that have received assistance from BioNova, which is guiding local manufacturers through Health Canada’s process of regulatory approval. The stakeholder advocacy group is providing companies with all the necessary documents to produce the PPE, and has engaged a local regulatory consultant to make submissions to Health Canada.

“There are applications where people are looking at alternative materials versus what has been approved, so they will need to prove that the new material is as effective as the existing,” said Moffitt. “So there’s going to be a fair amount of data that’s required to do that.”

The goal, he added, is to reduce the time in between production and the moment the gear lands in the hands of health-care workers.

It’s the assistance that the companies are grateful for, including MacKenzie Atlantic, which is now producing face shields for the Nova Scotia Health Authority, along with BBI Group.

The machining, welding and fabrication manufacturing shop often works on defence contracts, but will soon be making 70,000 face shields per week.

“(BioNova) had assurance from Health Canada that they would receive approvals in record time,” said MacKenzie Atlantic co-owner Carmen MacKenzie.

She described the company’s venture into PPE production as a “whirlwind three weeks,” adding that staff at the NSHA and IWK Health Centre have been extremely helpful in ensuring the gear meets both theirs and Health Canada’s specifications.

Both MacKenzie and Gunderson at BBI Group said they’re happy to be doing their part to keep health-care workers and the public safe during the pandemic.

READ MORE: Child and spousal support not covered by government’s coronavirus emergency benefit plan

Questions about COVID-19? Here are some things you need to know:

Health officials caution against all international travel. Returning travellers are legally obligated to self-isolate for 14 days, beginning March 26, in case they develop symptoms and to prevent spreading the virus to others. Some provinces and territories have also implemented additional recommendations or enforcement measures to ensure those returning to the area self-isolate.

Symptoms can include fever, cough and difficulty breathing — very similar to a cold or flu. Some people can develop a more severe illness. People most at risk of this include older adults and people with severe chronic medical conditions like heart, lung or kidney disease. If you develop symptoms, contact public health authorities.

To prevent the virus from spreading, experts recommend frequent handwashing and coughing into your sleeve. They also recommend minimizing contact with others, staying home as much as possible and maintaining a distance of two metres from other people if you go out.

For full COVID-19 coverage from Global News, click here.

- ‘She gets to be 10’: Ontario child’s heart donated to girl the same age

- Bird flu risk to humans an ‘enormous concern,’ WHO says. Here’s what to know

- Shoppers faces proposed class action over claims company is ‘abusive’ to pharmacists

- ‘Bacterial vampirism’: Deadly pathogens attracted to human blood, study finds

Comments